Stability Testing in Cosmetic Products

Stability Test in Cosmetic Products (Shelf Life Test)

What is a stability test?

A stability test in cosmetic products is a test conducted to determine how the formulation, packaging, and production process of a product behave under specific conditions. These tests are important to ensure the quality, durability, and safety of products.

Stability tests are generally conducted to determine the shelf life of products, monitor chemical and physical changes in the formulation, and evaluate the suitability of the product's packaging. These tests help determine how products will respond to storage conditions, temperature changes, light, humidity, and other environmental factors.

Stability tests typically focus on the following factors:

- Temperature: Conducted to determine how the product behaves under different temperature conditions (high temperature, low temperature). This evaluates the product's resilience to storage conditions.

- Light: Tested to monitor changes in the product's color or odor characteristics when exposed to sunlight.

- Air: Tested to monitor the oxidation or other chemical changes in the product when in contact with air.

- Packaging: Conducted to evaluate the packaging's ability to protect the product. This determines whether the packaging protects the product from external factors.

Stability tests are important to ensure the quality of cosmetic products and ensure consumer safety. These tests are usually conducted in accordance with international cosmetic regulations and standards, and products must successfully pass them before being launched onto the market. This ensures that products are stable, reliable, and effective.

Real-time stability testing is a test conducted to determine how a product behaves in real-world conditions and how long it can remain stable. This test allows the product to be monitored in real-time under conditions where it is exposed to natural environmental factors (temperature changes, humidity, light, etc.).

This test is important to determine how a product will perform under long-term storage conditions. Real-time stability testing typically involves monitoring the product under storage conditions for a specific period.

It is conducted to determine the product's resilience to environmental factors it may encounter during real-world use. As a result, it provides confidence to consumers about how long products can remain stable and usable.

Real-time stability testing is an important part of product development and quality control processes in the cosmetics industry and plays a critical role in product safety and efficacy.

Accelerated stability testing is conducted by subjecting a product to accelerated exposure to environmental factors (such as temperature, humidity, light) that it would normally be exposed to for long periods. This test allows the evaluation of the product's stability in a shorter period and estimation of shelf life.

This test is used in the early stages of product development to evaluate the impact of changes in formulation, packaging, and production processes on stability.

Accelerated stability tests are conducted by exposing the product to high temperatures, high humidity, intense light, or other environmental factors. While attempting to mimic the conditions the product would be exposed to over a long period, these factors significantly shorten the time (usually 3 months, 6 months, etc.).

The results of these tests provide valuable information about the product's stability and shelf life. Especially during the development of new products or formulations, accelerated stability tests are used to quickly assess product performance and identify potential issues.

However, accelerated stability tests cannot fully mimic real-world conditions and may be misleading in some cases. Therefore, they are usually used in conjunction with regular stability tests, and the results are carefully evaluated.

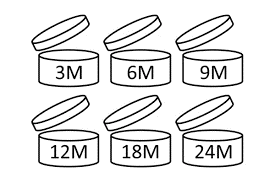

Period After Opening (PAO) / Open Packaging Stability Tests are conducted to determine the period during which a product can be safely used after opening. Open packaging stability involves testing and evaluating the product's physical and chemical properties at room temperature without degradation. The duration at the end of the test represents the time the product can be safely used after opening. This is indicated on the cosmetic product label as shown in the visual.